The most widely used vacuum-producing equipment in the industry is Liquid Ring Vacuum Pumps. The Liquid Ring Vacuum Pump Working Principle and Pumping System are discussed in this article.

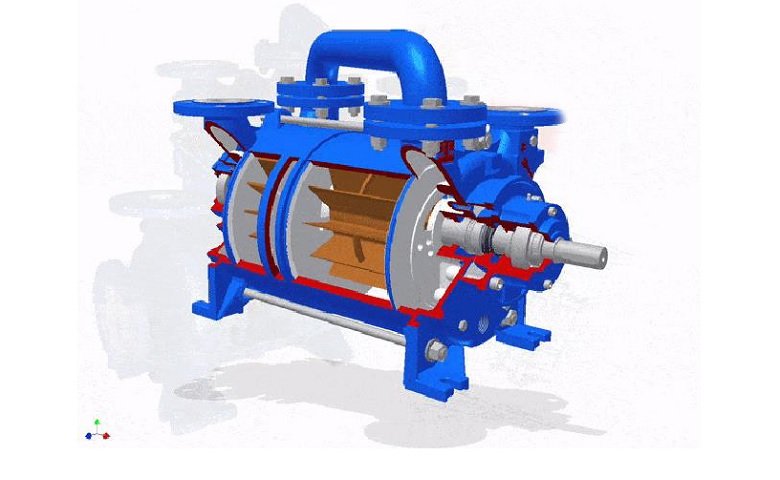

The liquid ring vacuum pump is made out of an impeller that is eccentric to the cylinder body (Vacuum pump housing). A liquid seal is used to produce a vacuum in the vacuum pump. Water is the most often used liquid sealant. Oil and a water-methanol combination are the other liquid sealants utilized in the vacuum pump.

The liquid (sealant) is poured to a minimum of 14% of the cylinder capacity before the vacuum pump is started. The impeller in a vacuum pump is sandwiched between two port plates. The port plates, which have shaped holes cut into them called ports, serve as the suction and discharge of the vacuum pump.

The “impeller cell” is the space between the impeller vane and the liquid. Consider a vacuum pump with an impeller cell at the top that revolves in a clockwise manner

The sealed liquid filled the cell at the top of an impeller. The liquid recedes from the impeller centre as the impeller rotates, creating a vacuum in the impeller cell. As a result, air or gas/vapour is pulled from the vessel, which must be kept at vacuum, through the Inlet port on the impeller’s sides. The sealant liquid is driven back toward the impeller’s centre hub after the impeller cell passes through the inlet port and travels toward the discharge port.

As the impeller cell approaches the discharge port, the pressure increases, and the gases, as well as part of the liquid sealant, are vented to the environment through the discharge port. Although the figures depict a smooth ring of liquid, the liquid sealant is really somewhat turbulent, which is why part of it is expelled with the gases. The cycle is done once again.

System for Vacuum Pumping

The overall configuration of the liquid ring vacuum pumps, separator vessel, and related pipes and connections is referred to as a vacuum pump system. There are three different types of vacuum pump systems. They really are.

- A system with a Single Pass

- System of Partial Recirculation

- System of Total Recirculation

- The vacuum pump system that is chosen is determined by the requirement or application for which the pump is being utilised.

Advantages:

- This technology is easy to use and has a cheap initial investment.

- Used in less serious situations.

Disadvantages:

- The amount of sealing liquid consumed is really high.

If you are willing to buy a Liquid Ring Vacuum pump, buy the same from the best store online. Stay refreshed to find more updates from Press KS, keep updated to our notification alers.